1. Kev xaiv raw khoom

High-Quality Melamine Resin: Cov txheej txheem tsim khoom pib nrog kev xaiv cov khoom zoo melamine resin, uas yog lub hauv paus rau tag nrho cov khoom. Lub purity ntawm cov resin cuam tshuam rau lub zog, kev nyab xeeb, thiab cov tsos ntawm cov khoom noj khoom haus zaum kawg. Cov neeg tsim khoom yuav tsum tau txais cov khoom lag luam zoo tshaj plaws los ntawm cov neeg muab kev ntseeg siab kom ntseeg tau cov khoom zoo ib yam.

Additives thiab Colorants: Kev nyab xeeb thiab khoom noj khoom haus-qib additives thiab colorants yog qhov tseem ceeb rau kev ua tiav qhov xav tau tiav thiab xim ntawm melamine dinnerwares. Ua kom ntseeg tau tias cov tshuaj ntxiv no ua raws li cov qauv kev nyab xeeb thoob ntiaj teb, xws li FDA lossis LFGB, yog ib kauj ruam tseem ceeb hauv kev tswj cov khoom lag luam.

2. Moulding thiab Shaping

Compression Moulding: Thaum cov ntaub ntawv raw tau npaj lawm, lawv tau txais cov txheej txheem compression molding. Melamine hmoov yog muab tso rau hauv pwm thiab raug kub siab thiab kub. Cov txheej txheem no pab tsim cov khoom noj hmo rau hauv daim phiaj, tais, khob, thiab lwm yam uas xav tau. Precision nyob rau hauv molding yog ib qho tseem ceeb kom tsis txhob muaj qhov tsis xws luag xws li qhov chaw tsis sib xws, tawg, lossis npuas npuas.

Tooling Maintenance: Cov pwm thiab cov cuab yeej siv hauv shaping melamine dinnerwares yuav tsum tsis tu ncua thiab ntxuav kom tsis txhob muaj qhov tsis xws luag. Hnav los yog puas pwm tuaj yeem ua rau tsis sib xws ntawm cov khoom loj thiab cov duab, cuam tshuam qhov zoo.

3. Thaum tshav kub kub thiab kho txheej txheem

Kub-kub Curing: Tom qab molding, cov khoom raug kho ntawm qhov kub thiab txias kom cov khoom tawv thiab ua tiav nws lub zog kawg. Cov txheej txheem kho yuav tsum tau ua tib zoo tswj xyuas kom ntseeg tau tias cov melamine resin tag nrho polymerizes, ua rau cov khoom siv ruaj khov, kub-resistant uas tuaj yeem tiv taus kev siv txhua hnub.

Kev sib xyaw ua ke hauv qhov kub thiab txias: Cov neeg tsim khoom yuav tsum tswj xyuas qhov tseeb ntawm qhov kub thiab qhov ntev. Txhua qhov kev hloov pauv tuaj yeem cuam tshuam rau kev ncaj ncees ntawm cov khoom noj khoom haus, uas ua rau muaj kev kub ntxhov lossis brittleness.

4. Nto xov thiab kho kom zoo nkauj

Polishing thiab Smoothing: Tom qab kho, cov khoom yog polished kom tiav ib tug du, ci ntsa iab nto. Cov kauj ruam no yog qhov tseem ceeb rau kev zoo nkauj thiab kev nyiam huv, vim tias qhov chaw ntxhib tuaj yeem cuam tshuam cov khoom noj khoom haus thiab ua kom huv si nyuaj.

Decal Application thiab Printing: Rau cov khoom noj khoom haus melamine dai kom zoo nkauj, cov tuam txhab lag luam tuaj yeem siv cov decals los yog siv cov txheej txheem luam ntawv los ntxiv cov qauv lossis cov khoom lag luam. Cov qauv tsim no yuav tsum tau ua tib zoo siv los xyuas kom meej qhov sib xws thiab adhesion, thiab lawv yuav tsum raug kuaj xyuas kom tiv thaiv kev ntxuav thiab kub raug.

5. Kev Tswj Xyuas Zoo thiab Kev Tshawb Fawb

In-Process Inspection: Cov neeg tsim khoom yuav tsum siv cov kev kuaj xyuas zoo ntawm txhua theem ntawm kev tsim khoom, los ntawm kev tshuaj xyuas cov khoom siv raw mus rau qhov kawg ntim. Qhov no suav nrog kev tshuaj xyuas qhov muag, kev ntsuas, thiab kev sim ua haujlwm kom ntseeg tau tias cov khoom ua tau raws li qhov tshwj xeeb.

Kev Xeem Thib Peb: Kev ywj pheej, kev ntsuam xyuas thib peb rau kev nyab xeeb khoom noj, ua kom ntev, thiab ua raws li cov qauv thoob ntiaj teb (xws li FDA, EU, lossis LFGB) ntxiv ib txheej ntxiv ntawm kev ruaj ntseg rau B2B cov neeg yuav khoom. Cov kev ntsuam xyuas no tshawb xyuas cov tshuaj xws li formaldehyde, uas tuaj yeem tsim kev puas tsuaj yog tias tswj tsis raug thaum lub sijhawm tsim khoom.

6. Qhov kawg khoom kuaj

Poob thiab Stress Test: Cov neeg tsim khoom yuav tsum ua qhov kev sim ua kom ntev, xws li kev sim poob thiab kev ntsuas kev ntxhov siab, kom ntseeg tau tias cov khoom noj khoom haus melamine tuaj yeem tiv taus qhov kev siv txhua hnub tsis muaj chipping lossis tawg.

Kub thiab Stain Resistance Test: Kev ntsuas kev tiv thaiv kom sov, txias, thiab staining yog qhov tseem ceeb, tshwj xeeb tshaj yog rau cov khoom lag luam rau kev lag luam khoom noj khoom haus. Cov kev ntsuam xyuas no xyuas kom meej tias cov khoom noj khoom haus yuav tsis degrade nyob rau hauv cov xwm txheej hnyav.

7. Ntim thiab xa khoom

Kev Tiv Thaiv Ntim: Kev ntim khoom kom zoo yog qhov tseem ceeb los tiv thaiv kev puas tsuaj thaum caij tsheb npav. Cov neeg tsim khoom yuav tsum siv cov ntaub ntawv poob siab thiab cov txheej txheem ntim kom ruaj ntseg kom ntseeg tau tias cov khoom tuaj txog hauv qhov zoo.

Ua raws li Shipping Standards: Ua kom lub ntim tau raws li cov qauv kev xa khoom thoob ntiaj teb pab tiv thaiv kev lis kev cai qeeb thiab ua kom muaj kev nyab xeeb thiab xa khoom raws sijhawm rau tus neeg yuav khoom.

8. Kev txhim kho tsis tu ncua thiab ntawv pov thawj

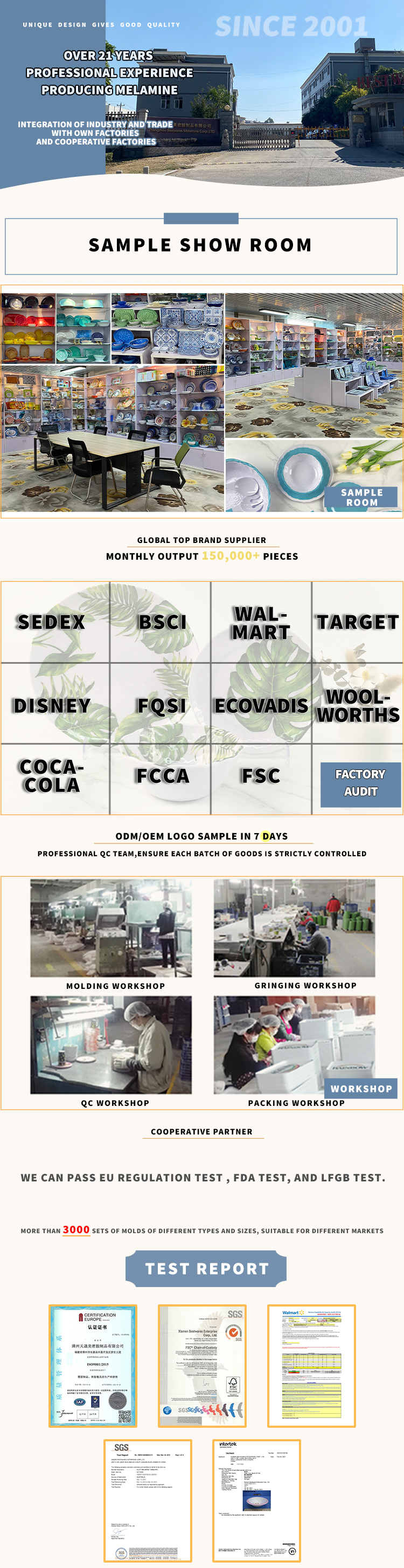

ISO Certification thiab Lean Manufacturing: Ntau lub tuam txhab ua lag luam tau txais kev txhim kho txuas ntxiv xws li kev tsim khoom lag luam lean thiab nrhiav ISO certification. Cov kev coj ua no pab txhim kho kev ua tau zoo, txo cov khoom pov tseg, thiab ua kom cov khoom zoo sib xws.

Supplier Audits: B2B cov neeg yuav khoom yuav tsum ua qhov tseem ceeb rau cov tuam txhab lag luam uas ua haujlwm tsis tu ncua ntawm lawv tus kheej cov txheej txheem thiab cov neeg muag khoom. Cov kev tshuaj xyuas no pab xyuas kom tag nrho cov saw hlau ua raws li cov qauv zoo, txo qhov kev pheej hmoo ntawm qhov tsis xws luag lossis tsis ua raws.

Txog Peb

Post lub sij hawm: Aug-23-2024