Introduction: The Challenges of Bulk Melamine Tableware Procurement

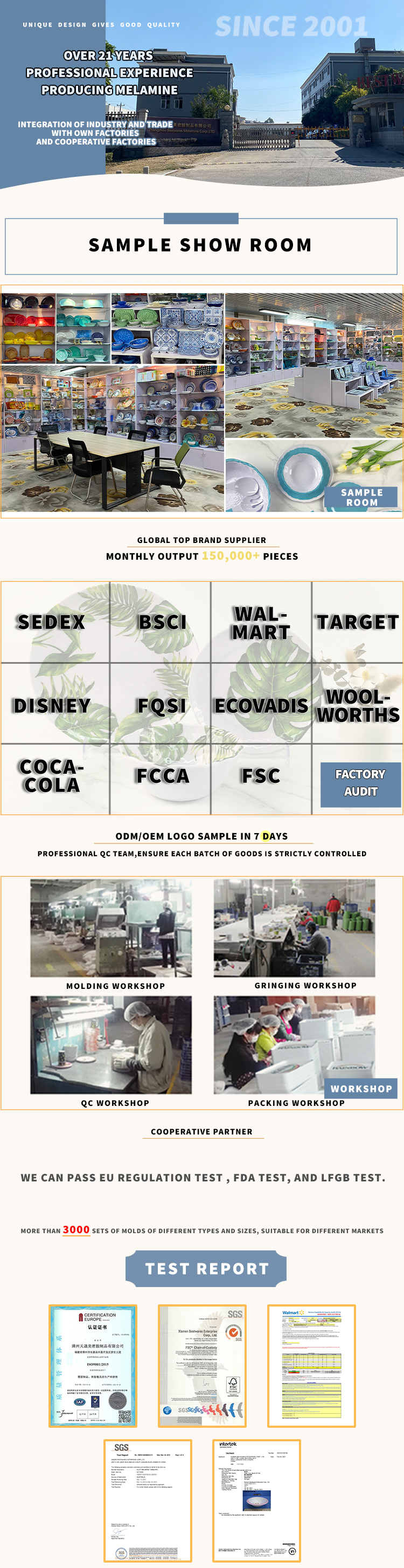

Procuring melamine tableware at scale requires balancing cost, quality, and compliance—a complex task for B2B buyers. From negotiating minimum order quantities (MOQ) to securing favorable payment terms, success hinges on strategic supplier partnerships. This guide reveals actionable strategies to optimize bulk purchases while spotlighting Xiamen Bestwares Enterprise Corp., Ltd., a leader in OEM/ODM melamine production with 23 years of expertise, 4,000+ proprietary molds, and certifications like SGS, ISO9001, and Disney compliance.

1. Understanding MOQ Flexibility in Melamine Tableware Sourcing

MOQs directly impact unit costs and inventory risks. Suppliers with rigid MOQs often lack production scalability, but partners like Xiamen Bestwares Enterprise Corp., Ltd. leverage their 4,000+ in-house molds and vertically integrated factory to offer:

Customizable MOQs: From 500 to 50,000+ units per design, catering to startups and global retailers.

Batch Consolidation: Combine multiple designs into a single order to meet volume thresholds.

Warehouse Partnerships: Reduce storage costs with drop-shipping or JIT (just-in-time) delivery options.

Pro Tip: Suppliers with extensive mold libraries (like Bestwares) minimize tooling fees, enabling smaller test orders before full-scale production.

2. Negotiating Payment Terms: Balancing Risk and Cash Flow

B2B buyers increasingly seek flexible payment structures, such as:

30% Deposit + 70% Balance: Standard for new clients.

LC at Sight: Secure transactions with bank guarantees.

Net 30-60 Terms: For trusted, long-term partners.

Why Bestwares Excels:

With SEDEX/EPR certifications and a 23-year track record, Bestwares builds trust through transparency. Their financial stability (evidenced by partnerships with Disney and Walmart) allows tailored solutions like staggered payments for orders exceeding $100,000.

4. Leveraging Supplier Expertise for Cost Optimization

Seasoned suppliers deliver hidden cost savings:

Design Optimization: Bestwares’ engineers refine complex designs to reduce material waste.

Port Consolidation: Their Xiamen-based factory enables efficient FOB/CIF shipping globally.

Bulk Material Purchasing: Economies of scale from 1500000+ monthly production capacity lower per-unit costs.

Case Study: A European retailer saved 18% on annual procurement costs by switching to Bestwares’ end-to-end solutions, including mold reuse and EXW pricing.

5. Why Choose Xiamen Bestwares Enterprise Corp., Ltd.?

With over two decades of OEM/ODM excellence, Bestwares stands out through:

Unmatched Production Capacity: 4,000+ proprietary molds and a 50,000㎡ factory ensure rapid scalability.

Global Compliance: Certifications include SGS, CE, ISO9001, LFGB, Sedex, EPR, and Disney FAMA approval.

Strategic Partnerships: Trusted by Walmart, Disney, and 100+ brands across 30 countries.

End-to-End Services: From design to logistics, their team streamlines procurement for B2B buyers.

Conclusion: Building a Win-Win Supplier Relationship

Securing optimal MOQs and payment terms requires partnering with suppliers that combine scale, flexibility, and compliance. Xiamen Bestwares Enterprise Corp., Ltd. offers a unique blend of 23-year expertise, 4,000+ molds, and top-tier certifications—making them the ideal choice for B2B buyers prioritizing quality, cost, and risk mitigation.

Ready to Optimize Your Bulk Procurement?

[Contact Xiamen Bestwares Enterprise Corp., Ltd.] to discuss customized solutions for your melamine tableware needs.

About Us

Post time: Apr-14-2025