Revolutionizing Inventory Management: The Rise of VMI in Melamine Tableware Supply Chains

As B2B buyers and suppliers grapple with volatile demand and rising warehousing expenses, Vendor-Managed Inventory (VMI) has emerged as a game-changer for the melamine tableware industry. By shifting inventory responsibility to suppliers, businesses can slash carrying costs while ensuring seamless stock availability—a critical advantage for sectors like hospitality and catering. Here’s how leading suppliers and buyers are making VMI work.

Why VMI Works for Melamine Tableware

Cost Efficiency: Suppliers monitor real-time sales data to replenish stock proactively, minimizing overstocking and stockouts. Buyers reduce capital tied up in excess inventory.

Demand Responsiveness: VMI enables rapid adjustments to seasonal spikes (e.g., wedding season) or supply chain disruptions.

Sustainability Gains: Optimized ordering reduces waste from unsold or obsolete inventory, aligning with eco-conscious procurement goals.

Steps to Implement VMI Successfully

Data Transparency: Integrate ERP or IoT-enabled platforms to share sales forecasts, inventory levels, and consumption patterns with suppliers.

Define KPIs: Agree on metrics like fill rate (e.g., 98% order accuracy), lead times, and inventory turnover ratios.

Risk-Sharing Contracts: Structure agreements where suppliers absorb partial overstock risks in exchange for longer-term commitments.

A European catering supplier partnered with a Turkish melamine manufacturer to pilot VMI. By granting the supplier access to POS data from 200+ restaurant clients, the manufacturer streamlined deliveries to match weekly consumption trends. Results:

30% lower warehousing costs.

25% faster order fulfillment.

15% reduction in material waste.

Overcoming VMI Adoption Challenges

Trust Barriers: Start with a limited product range or regional pilot before scaling.

Tech Integration: Use cloud-based tools like SAP S/4HANA or Oracle NetSuite for synchronized data sharing.

Supplier Incentives: Offer volume guarantees or early payment discounts to motivate supplier participation.

Trust Barriers: Start with a limited product range or regional pilot before scaling.

Tech Integration: Use cloud-based tools like SAP S/4HANA or Oracle NetSuite for synchronized data sharing.

Supplier Incentives: Offer volume guarantees or early payment discounts to motivate supplier participation.

The Future of VMI: AI and Predictive Analytics

Forward-thinking suppliers are leveraging AI to predict demand shifts (e.g., post-pandemic tourism rebounds) and automate replenishment. For instance, India’s EcoMelamine uses machine learning to adjust production schedules based on global hospitality booking trends, cutting stockholding costs by 22%.

About Us

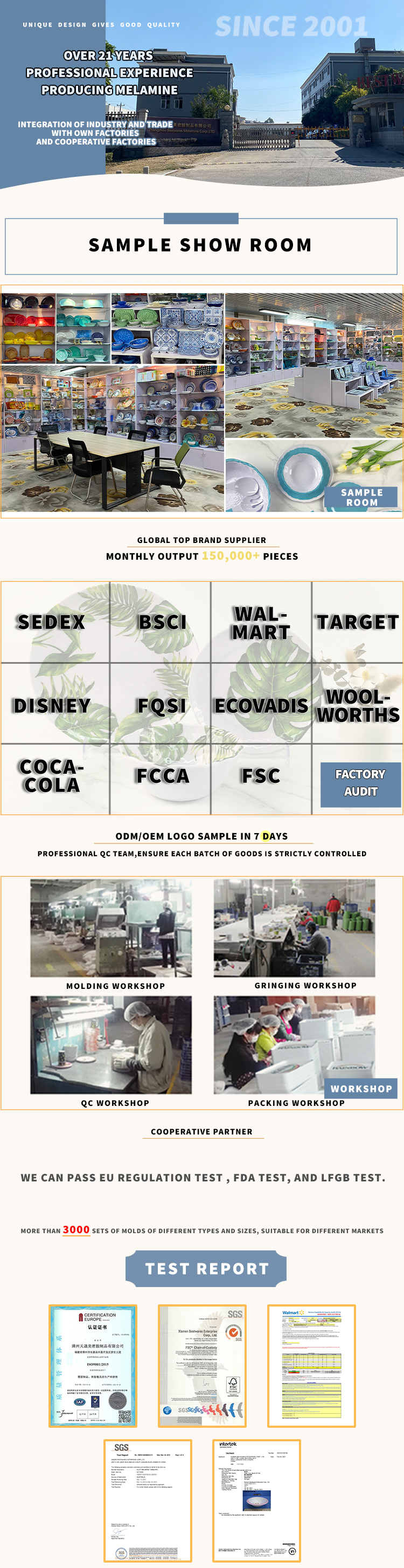

Xiamen bestwares empowers B2B buyers and suppliers to adopt innovative inventory models like VMI through integrated tech solutions and a curated network of certified melamine tableware manufacturers. Our platform bridges data gaps, ensuring transparency and efficiency across the procurement lifecycle.

About Us

Post time: Apr-27-2025